Feb 28, 2018 · Single screw forming extruders are used to manufacture pasta, processed meats, and fillings. Single screw cooking extruder (SSCE) are used to produce dry and semi moist pet foods, expanded snacks, breakfast cereals, puddings, soup and drink bases, gelatinized starch and texturized vegetable proteins. Twin-screw extruder applications include

The actual single screw extrusion process is shown in Fig. 6.Further, Table 3 shows the specifications of single screw extrusion process used in the present study. The critical input parameters for extrusion process are screw speed, exit die temperature, speed of take up unit, temperature of water tank, screw barrel temperature, and die nozzle diameter.

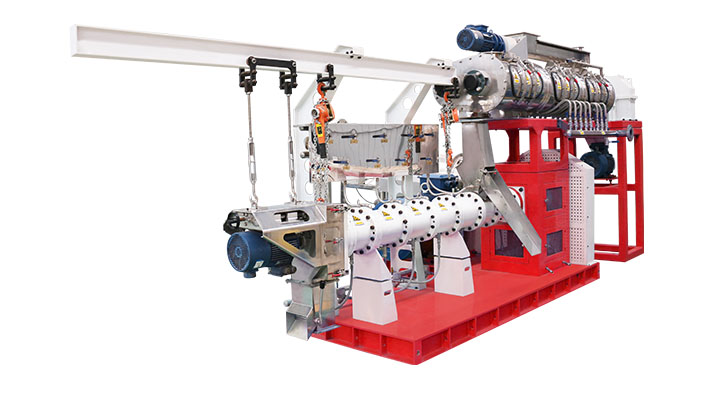

The EX Series of single screw extruders represents state-of-the-art technology, ensuring unique quality feed at minimum operating costs with a high degree of processing flexibility Watch our product animation to see the EX Series in action and download the datasheets for technical details, sizing, and options.

Oct 4, 2014 · An initial investigation into the inclusion of soy white flakes (SWF) and high protein distillers dried grains (HP-DDG) in catla (Catla catla) diet, belonging to the family Cyprinidae, was conducted using a single screw extruder. Three isocaloric (302 kcal/100 g) ingredient blends containing graded levels of SWF in combination with HP-DDG and other required ingredients were formulated to

.jpg)

Apr 5, 2004 · The single-screw extruder from Buhler continuously converts starches, proteins and fats. It can be used for numerous applications including fish feed. During the extrusion process, the starch-containing feed components are broken up and the proteins are denatured.

.jpg)

Single screw extruders are most popular for their low cost, simple designs, ruggedness, and reliability. Typical sizes vary from 1 to 6 inch (25 to 150 mm) and L/D ratio from 20 to 30 with 24 being most common. Basic operation of a single screw extruder is described in the earlier section.

May 5, 2007 · Effects of extrusion variables on extrudate characteristics of fish muscle-rice flour blend containing intermediate moisture (30–50%) were studied in an indigenously developed single screw cooking extruder.

As the leading professional fish feed production line and fish feed machine series manufacturer, FANWAY Fish Feed Machinery has released two types of single screw fish feed extruders – dry type and wet type fish feed extruders so as to meet the ever-increasing demand for fish feed pellet production.

It is measured in outside diameter most extruders are between .75”-10”. The most popular sizes are 1.5”, 2.5”, 3.5” 4.5 and 6”. The effective length of the extruders typically 24-36 L/D although can be shorter or longer for specialized applications. The L/D of a single screw extruder is the ratio of the length over the diameter.

Nov 11, 2014 · Single-screw extruders are used to produce virtually all of the extruded soybeans in livestock feeding. Twin-screw technology involves much higher capital costs — about 1.5 to 2.5 times higher than a state-of-the-art single-screw extruder of comparable hourly production capacity.

.jpg)

Oct 6, 2021 · 64 DESIGN, FABRICATION AND PERFORMANCE EVALUATION OF A SINGLE SCREW EXTRUDER FOR THE PRODUCTION OF FLOATING FISH FEED Olalusi, A.P., Olaoye, S. A. Oyerinde, A. S

The locally developed floating fish feed extruder was evaluated for performance in terms of machine parameters such as; screw speeds (158.5, 225 and 334 rpm), die size (4, 6 and 8 mm) and moisture content of feed materials (20, 30, 40 and 50%), on specific mechanical energy requirements, expansion ratio, bulk density and pelleting efficiency were determined.

What is feed extrusion and what are its benefits? Feed extrusion is a process used to create shaped products from a variety of materials. It can be used to create pellets, flakes, or other shapes from a variety of feedstock materials. The benefits of feed extrusion include the ability to create products with specific shapes and sizes, as well as the ability to add special coatings or

There are two kinds of extruders that might be used in aquafeed production: the single-screw extruder and the twin- screw extruder. Single-screw extruder: As its name implies, a single-screw extruder has only one extruding screw and is of simple structure, so its price is relatively lower.

Aug 15, 2022 · Design, Fabrication and Performance Evaluation of a Single Screw Extruder for the Production of Floating Fish Feed August 2022 Journal of Scientific Research and Reports 28(10):1-10